The Sand Blaster For Sale Statements

Table of ContentsSome Known Incorrect Statements About Portable Sandblaster Mobile Sandblasting Near Me for BeginnersLittle Known Questions About Abrasive Blasting.About Abrasive BlastingAll about Abrasive BlastingSand Blaster Harbor Freight Things To Know Before You Get This

Damp unpleasant blasting [modify] Wet rough blowing up uses water as the liquid relocating the abrasives. The benefits are that the water traps the dust produced, and lubes the surface area. The water cushions the effect on the surface area, reducing the elimination of sound product. One of the original leaders of the damp abrasive procedure was Norman Ashworth that discovered the advantages of making use of a wet procedure as a strong choice to completely dry blowing up.

Minimized impregnation of blasting product right into the surface area, dirt reduction as well as the elimination of fixed stick can result in an extremely tidy surface - sand blaster for sale. Wet blasting of moderate steel will cause instant or 'flash' rust of the blown up steel substratum as a result of the visibility of water. The absence of surface area recontamination also permits the use of single devices for multiple blowing up operationse.

Facts About Abrasive Blasting Uncovered

A variation of wet blasting is vapor blasting (or vapour blasting; U.K.). In this process pressurized air is included to the water in the nozzle generating a high speed haze, called "vapor". This process is even milder than damp blowing up, allowing mating surface areas to be cleansed while keeping their capability to mate.

Blending bits with water significantly minimizes dirt. Bead blasting is the process of removing surface area down payments by using fine glass grains at a high stress without damaging the surface.

In removing paint for vehicle body work, grain blasting is preferred over sand blasting, as sand blasting has a tendency to create a higher surface area profile than bead blasting. Bead blasting is often made use of in creating a consistent surface coating on machined components. It is furthermore utilized in cleansing mineral samplings, many of which have a Mohs firmness of 7 or much less and would thus be harmed by sand.

The Best Strategy To Use For Abrasive Blasting

The initial blast wheel was patented by Wheelabrator in 1932. In China, the initial blast wheel was constructed around the 1950s, Qinggong Machinery is just one of the earliest manufacturers of blast wheel. Hydro-blasting [modify] Hydro blowing up is not a type of unpleasant blowing up as no abrasive media is used. Hydro-blasting, typically understood as water blasting, is frequently utilized due to the fact that it typically requires just one operator.

This method is perfect for cleansing internal as well as outside surfaces since the operator is generally able to send out the stream of water click now into locations that are tough to get to utilizing various other techniques. One more advantage of hydro-blasting is the capacity to recapture and recycle the water, reducing waste and also mitigating environmental influence.

The most typical micro-abrasive blasting systems click to investigate are commercial bench-mounted devices consisting of a power supply and mixer, exhaust hood, nozzle, and also gas supply. Either the nozzle or part can be moved in automatic procedure.

Sandblaster For Sale Things To Know Before You Get This

Automated blowing up is often simply a step in a larger automated treatment, normally involving other surface area treatments such as prep work and also finish applications. Care is frequently needed to separate the blasting chamber from mechanical components that may be subject to dirt fouling. Dry-ice blowing up [edit] In this kind of blowing up, air as well as completely dry ice are used.

The air compressor offers a big quantity of high stress air to a solitary or multiple "blast pots". Blast pots are pressurized, tank-like containers, loaded with abrasive material, utilized to enable an adjustable quantity of blasting grit into the primary blasting line. The variety of blast pots is determined by the quantity of air the compressor can provide.

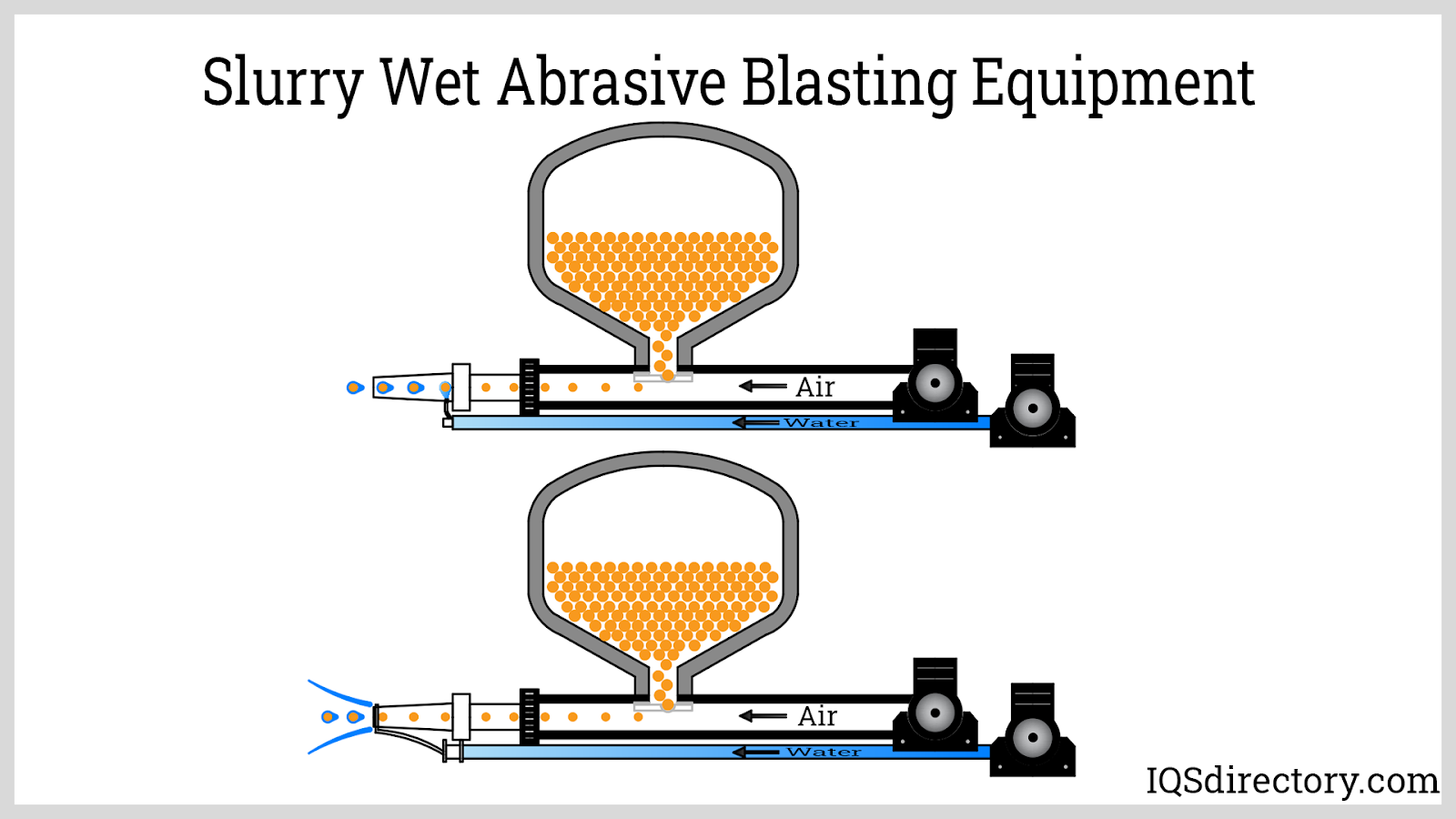

Others are receptacle-fed types making them light-weight as well as more mobile. In damp blowing up, the abrasive is presented into a pressurized stream of water or various other liquid, developing a slurry. sandblasting company Damp blowing up is usually utilized in applications where the marginal dirt generation is preferred. Mobile applications might or may not reuse the unpleasant.

The Single Strategy To Use For Shot Blasting Near Me

There are three systems generally made use of in a blast closet. Two, siphon as well as stress, are dry and one is damp: A siphon blast system (suction blast system) uses the compressed air to produce vacuum cleaner in a chamber (called the blast gun). The unfavorable stress pulls rough right into the blast weapon where the compressed air routes the abrasive with a blast nozzle.

Nozzles are available in a variety of shapes, dimensions, and materials. Tungsten carbide is the lining material most usually made use of for mineral abrasives. Silicon carbide as well as boron carbide nozzles are a lot more use resistant as well as are often utilized with tougher abrasives such as aluminium oxide. Low-cost abrasive blowing up systems and also smaller closets utilize ceramic nozzles.

Fascination About Sand Blaster Harbor Freight

The vessel is pressurized to the very same pressure as the blast tube affixed to all-time low of the pressure vessel. The rough is metered right into the blast hose as well as communicated by the compressed gas with the blast nozzle. Damp blast closets utilize a system that infuses the abrasive/liquid slurry right into a compressed gas stream.